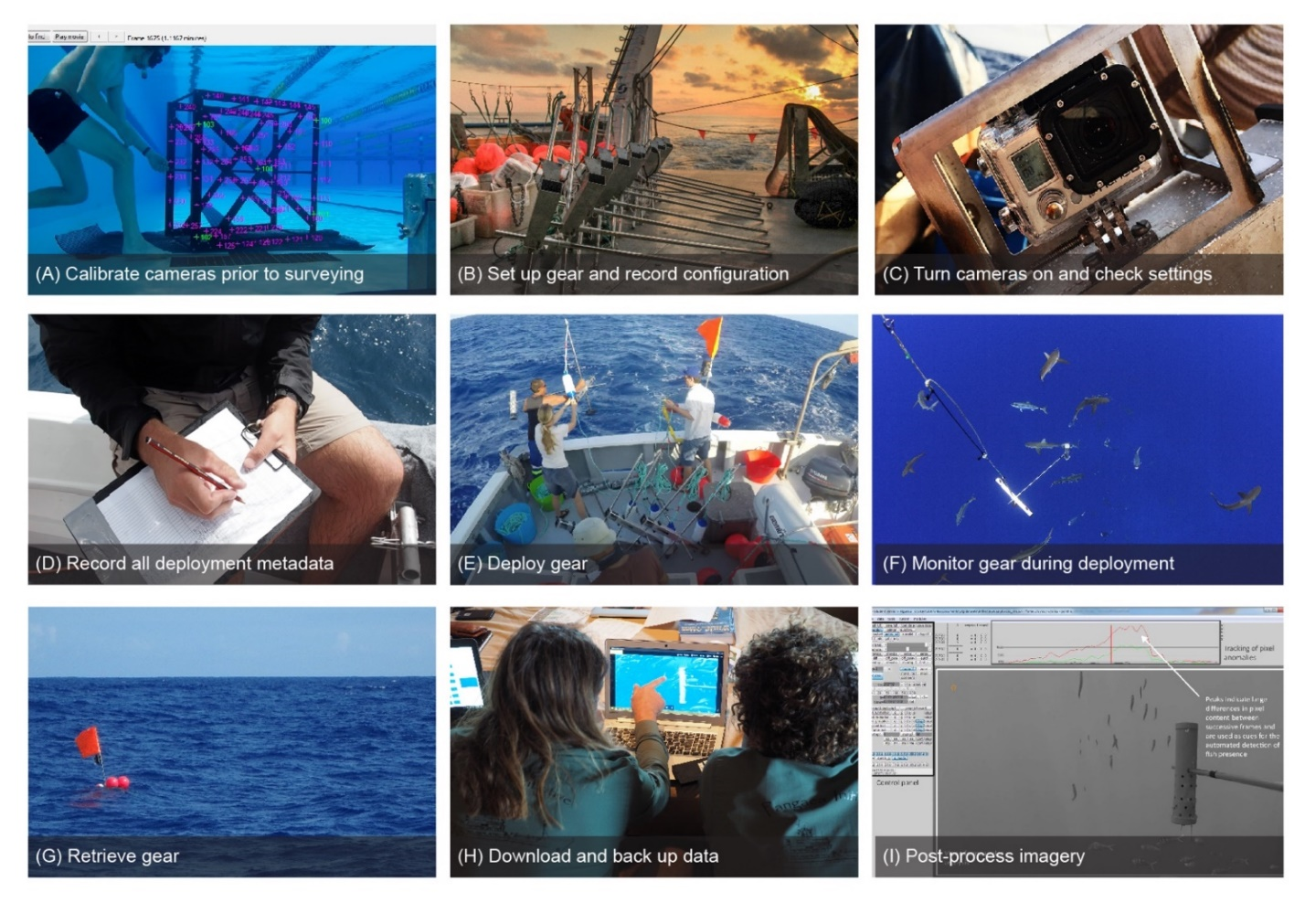

A visual summary of the key steps to follow when deploying pelagic BRUVs is shown in Figure 6.3.

Figure 6.3: Images from key steps involved in the use of pelagic BRUVs for marine monitoring. (A) Using a calibration cube in an enclosed pool environment. (B) Once set up, the gear can be easily stacked and stowed on deck. (C) Example of a GoPro camera turned on before deployment. (D) Relevant metadata can be recorded on waterproof paper. (E) Pelagic BRUVs are versatile and can be deployed manually from a variety of platforms ranging in size from small rigid inflatables to large research vessels. (F) Maintaining visual contact with the gear is key to avoiding equipment loss. Should the deployment vessel need to leave the site (e.g. to support additional activities), a VHF transmitter can be used to re-locate the gear. (G) Flags and brightly coloured buoys help locate the equipment for recovery. (H) Videos are typically downloaded and backed up at the end of each sampling day. (I) Processing and analysis of the imagery occur in a computer lab post-survey.

Calibrations

Stereo-BRUVs require calibration to ensure accurate length measurements. Calibration frequency will ultimately depend on the hardware used and recommendations from the manufacturer. Calibrations are best carried out prior to surveying and commonly take place in enclosed pool environments. Additional post-survey calibrations are also advantageous, particularly following long sampling campaigns where the risk of camera displacement during operation or transport is higher. The calibration process takes into account the base separation, camera angle and lens distortion, all of which are unique to each BRUV (Harvey & Shortis 1998), meaning that individual units must hence be calibrated separately, and cameras should not be swapped between units. In addition, if a camera is damaged or knocked out of position during field work, calibrations will need to be repeated post-survey. While some studies show that purpose-built three-dimensional calibration cubes yield maximum accuracy (Boutros et al. 2015), recent evidence suggests that planar checkerboards may be equally accurate, at a fraction of the cost (Delacy et al. 2017). Where possible, carrying out ‘mock deployments’ of a single unit may be useful to ensure the BRUV units sit correctly and consistently in the water column.

SeaGIS have long been the primary provider of third-party calibration hardware and software, yet alternative open-source packages have now also begun to emerge, including the MATLAB Calibration Toolbox or the StereoMorph R package (Olsen & Westneat 2015, Díaz-Gil et al. 2017).

Arrival on site

- Unpack equipment and check for any damage that may have occurred during transport.

- Check that all camera settings are correct (Table 6.3), batteries are full and memory cards formatted.

- If not already done, number each individual camera and memory card using a permanent marker, and make a note of which card is used in which camera on the data sheet. It may be useful to also number batteries and battery extension packs, to facilitate the troubleshooting of any hardware malfunctions.

- Lubricate the cameras’ O-rings and check them for cuts or nicks. Replace damaged O-rings as appropriate.

- Set up pelagic BRUV unit(s) (see Table 6.4 for an example). Attach bait containers to bait arms and securely stack/stow equipment on deck.

- Discuss deployment and safety plans with captain/crew/team and deliver a copy of sampling site coordinates to the skipper.

Table 6.4: Example instructions for setting up a pelagic BRUV. Note that BRUV components are often made of stainless steel to prevent rusting in the marine environment. All replacement parts (e.g. spare bolts, nuts etc.) must therefore also be marine grade stainless (316).

| Order | Action |

| Rigs | |

| Step 1 | Attach camera housings to the mounts on the crossbar using a stainless steel nylon locking nut and bolt (Phillips head 3/16” approx. 25mm). Ensure they are tightly in place and will not move if bumped. Do not remove after attachment to ensure calibration accuracy. |

| Step 2 | Place the upright through the hole in the centre of the rig and secure with locking nut. |

| Step 3 | Weight rigs by placing 2 x 2.5kg dumbbell weights (rubber coated preferable) on the base of the vertical pole in the centre and secure with a stainless steel lynch pin. |

| Step 4 | Place the loop of the 10m rig line into the shackle on the top of the rig upright, and ensure the shackle is done up tight (use mousing wire to ensure the shackle does not come loose with the movement of the rig in situ). |

| Step 5 | Fix the bait arm in place with a shark clip. |

| Bait canisters | |

| Step 6 | Take a ~50 cm length of PVC pipe, glue a cap on one end and a screw cap on the other. Once dry, use a power drill to drill small ~1-2 cm holes in the end without the screw cap and one large hole all the way through in the centre to allow the bait arm to fit through. Drill small holes in the cap at the holey end and cable tie a dive weight to the inside of the canister. |

| Lines | |

| Step 7 | Equip each rig with 10 m of rope. Note: The length of rope can be adapted depending on the suspension depth relevant to the project. |

| Step 8 | At one end of the loop, make a small (~15cm) eye by splicing the rope back on itself. This end will be attached to the rig upright. |

| Step 9 | At the other end, pass the line through the eyelet of a double action clip and splice it back on to itself to create a loop with the clip on the end. This will be attached to the longlines and buoys. |

| Step 10 | Close to the top of this line (~2 m down), tie on a short length of shock cord (~1 m), to create a D-shape with the shock cord making the short side. At the top of this tie using a small length of line to attach a small buoy. |

| Step 11 | Cut four 200 m lines for each set of 5 rigs (or 9 for sets of 10) to act as the long lines between rigs. |

| Step 12 | Splice small loops at the ends of each of these lines (~15 cm). |

| Step 13 | Store on a winch clipped together with shark clips to make one line. If a winch is not available coil the lines into separate nelly or rubber rope bins, keeping the ends free and easily accessible for deployment. |

| Buoys | |

| Step 14 | Inflate buoys using a compressor and needle. |

| Step 15 | Take a length of line (1.5-2 m works well) and thread through the eyelets of three buoys and splice it back on to itself, leaving about 1 m free. |

| Step 16 | Pass the free end through the eyelet of a double action clip and splice it back on itself to create a small loop with the clip on the end. You should be left with a loop with the three buoys and a 1m length with a clip at the end. Note: Smaller sub-surface buoys can also be added to the suspension line and will generally help stabilise the rig, thereby facilitating species identification and length measurements. |

| Step 17 | To deflate the buoys at the end of the expedition, simply unscrew the bung (some are flat head and some are Phillips head). |

| Step 18 | Inflation and deflation of buoys should be considered for storage and mobilisation (i.e. whether an air compressor is on board the work vessel and what attachment is required). |

| Cameras | |

| Step 19 | Two [insert model name, e.g. GoPro Hero 3] are required per rig plus spares. The night before field work is conducted, ensure that the camera settings are correct (Table 6.3) and that the cameras and battery packs are charged (power-boards, USB hubs and USB2 cords are the easiest way to do this) NOTE: adapters may be required if working overseas. |

| Step 20 | Once the cameras and battery packs are charged, store them in a Tupperware container lined with a layer of foam padding above and below (or a specifically fitted Pelican case) to keep them from moving around in transit. |

| Step 21 | Store in a cool dry place until needed. |

| Step 22 | Camera housings should be attached to rigs permanently. Consider the depth ranges being sampled and choose housing types accordingly. Standard GoPro housings are rated to 40 m while dive housings are rated to 60 m. This may vary amongst manufacturers and brands. External battery packs must be used to ensure that the cameras run for the required time. |

| Flag/GPS/VHF buoy | |

| Step 23 | Assemble using socket and spanner sets. |

| Step 24 | Make sure tension wires are tight. |

| Step 25 | Splice a 10 m length of line to the buoy, pass the opposite end through the eyelet of a double action clip and splice back on itself to fix in place. |

Deployment

- Take bait out of the freezer before sampling and place it in a rubber bin (empty or filled with seawater) to allow it to thaw. This can be done anywhere between 1 and 12 hours beforehand. Note that in tropical countries, bait loses texture and quality if thawed too early. It is also generally easier and cleaner to crush half-frozen bait than bait that has thawed fully.

- When on route to the drop location, rigs can be laid out in order with the first rig to be deployed closest to the stern (along with corresponding lines if a winch is not being used).

- Prepare bait (e.g. mince, slice or crush) and fill bait bags/canisters with desired weight.

- Seal bait canister (e.g. tighten screw caps) and store upright in a plastic container until use.

- Check that metadata sheets are ready (see Table 6.5). These sheets should be printed on waterproof paper before leaving for the expedition. Fill in drop numbers, camera numbers and memory card numbers when preparing cameras for the day’s work. Follow this in the field and fill in the other information as available.

- Attach lights and sensors, if available.

- If using a VHF transmitter, remove the magnet and note the device’s frequency, checking it is working correctly and a signal can be heard/detected. Place it in a small pelican case attached to the flag buoy, along with one GPS logger (turned on by holding down the middle button) and close tightly.

- Insert cameras into housings and check that the housings are dry and sand-/hair-free, without any other objects obstructing the O-rings to ensure a good seal.

- Turn the cameras on (e.g. for GoPros, by pressing the front button until the red light starts flashing and the timer starts), check there is battery and storage space available.

- Place the data sheet (or Magnadoodle/slate/white board/paper sheet) showing drop number, date, rig number and location in front of each camera and in the centre over the bait arm so that it is clearly seen in the fields of view of both cameras. Verbal logs are an alternative/complementary option, as modern cameras are usually sufficiently sensitive to record spoken instructions/information.

- Attach a diode to the bait arm if using stereo-BRUVs. If a diode is not available, clap slowly 3-4 times in front of the cameras (using a clapperboard or bare hands) over the bait arm in clear view to allow synchronisation during video analysis.

- Attach the flag pole, one cluster of buoys and the first of the rigs to be deployed to the end of the first longline via double action clips. Ensure the rope is free, coiled, and facing the correct direction to un-coil without hindrance

- At the captain’s go-ahead (i.e. vessel in position and stationary), drop the flagpole into the water.

- Once the flagpole is clear, push or throw the first rig so that it clears the side of the boat, ensuring all lines are clear of feet and untangled. Drop the cluster of buoys over first, followed by the rig ensuring not to drop the rig on any of the other lines in the water. This works best if one person handles the buoys and another the rig. Note that this sequence differs slightly for moored BRUVs, which require the ballast/anchor to be dropped first, followed by the rig and the floats in this order.

- Mark a GPS waypoint when the unit is deployed and record both deployment time and site coordinates on the data sheet, which will have been pre-populated with location, rig number, camera numbers, memory card numbers etc. Include comments where necessary e.g. issues, weather conditions.

- For single-rig designs, travel to the next site. For multi-rig designs, repeat until all units are in the water, making sure the captain moves forward slowly to pay out the lines.

Table 6.5: Example metadata sheet for pelagic stereo-BRUV fieldwork. Left and right memory card numbers must be recorded for each camera pair.

| Date | ID | Rig | Left cam | Left card | Right cam | Right card | Time in | Location in | Time out | Location out | Comments (e.g. wildlife, behaviour, habitat etc.) |

| 2017-10-25 | SITE-A | 15 | 12 | 05 | 10 | 02 | 08:00 | (115.1252E; 32.5437S) | 10:15 | (115.2411E; 32.5008S) | Seabird aggregation observed near deployment site |

Retrieval

- Manoeuvre the vessel alongside the flag/grappling buoy, heading upwind of the current towards the BRUV.

- Either gaff or grapple the rope joining to flag buoy to the first cluster of buoys.

- Haul the line in and retrieve the flag buoy, taking care not to knock the tension wires on the stern of the boat. Remove and store the VHF transmitter and GPS logger when convenient. Wear gloves when hauling and coiling. Pelagic BRUVs are relatively light so manual handling is generally possible, however use a winch or pot hauler if available and warranted.

- Unclip buoys and coil rope to facilitate future deployments.

- Turn off the cameras, rinse them with freshwater, dry the seals around the housings with a towel and carefully remove the cameras from their housings when convenient. If conducting surveys over multiple days, it is good practice to clean and re-grease the O-rings with silicone at regular intervals.

- Store the rig and buoys out of the way.

- Repeat until all units are retrieved.

- Remove memory cards.

- If required, charge or change camera batteries.

- Either setup the equipment for redeployment or securely stow on deck.